Ever since we added Universe to celebrate our 10th anniversary last year, I’ve wanted to weave with it. A mix of linen, cotton, metallic, wrapped together with nylon, I swear there’s a bit of magic in every strand. The combination of plant fibers and sparkle mesmerizes me.

It’s beautiful in knitted items, such as the Planetary Shawl:

Or the delightful Universe of Snowflakes:

But I knew Universe would make beautiful weaving, too. I decided this was the project I would finally warp up my poor, neglected floor loom. My Fanny Leclerc has been sitting as a backdrop for my rigid heddle weaving these last few years, as though I’m mocking her abilities as a workhorse weaver. She’s a sturdy 4-shaft loom procured a number of years back at a reasonable price via my local Craigslist.

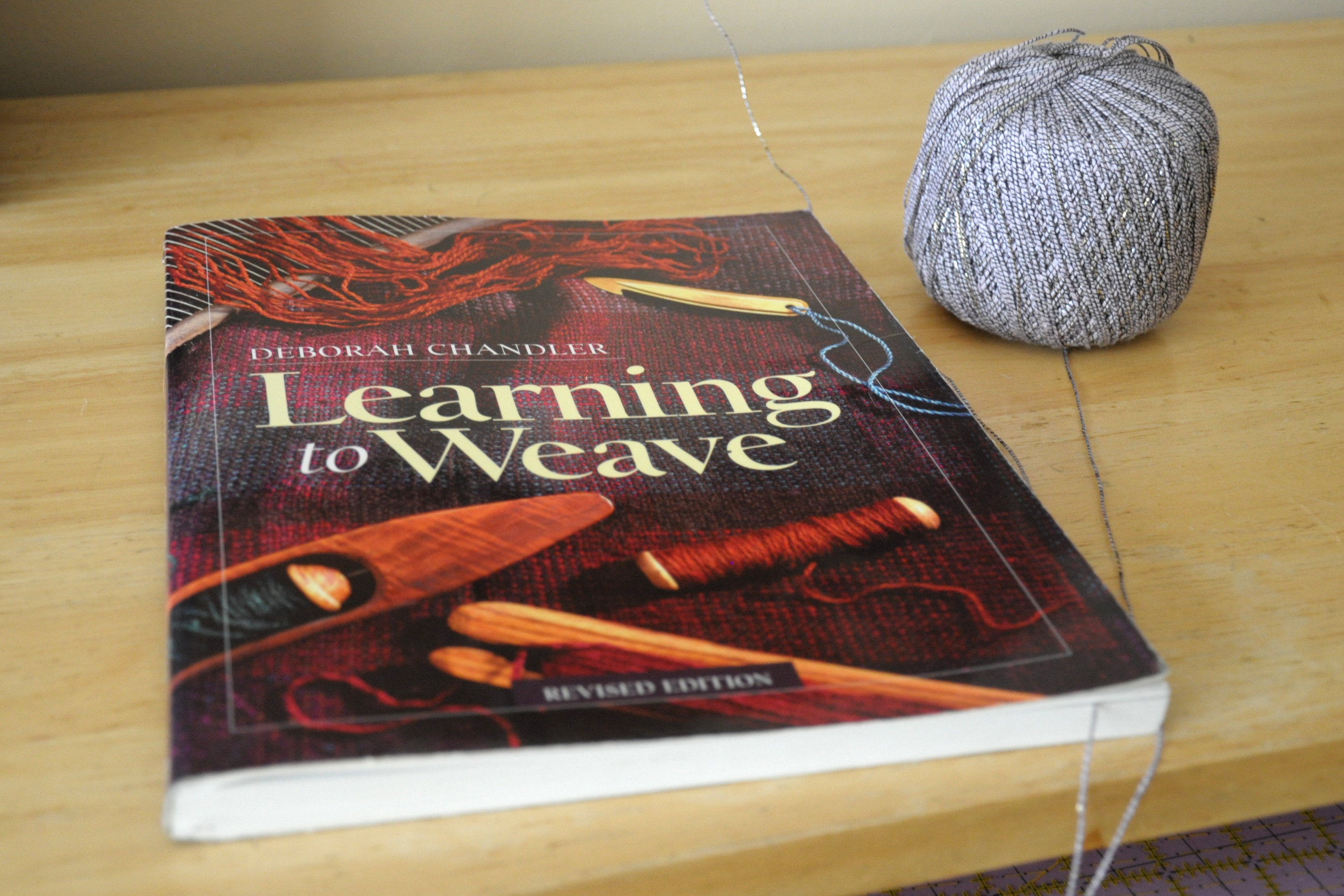

But first things first. It’s been years since I wove on Fanny, and I needed a refresher on warping. Luckily, I had my trusty copy at hand of “Learning to Weave” by Deborah Chandler.

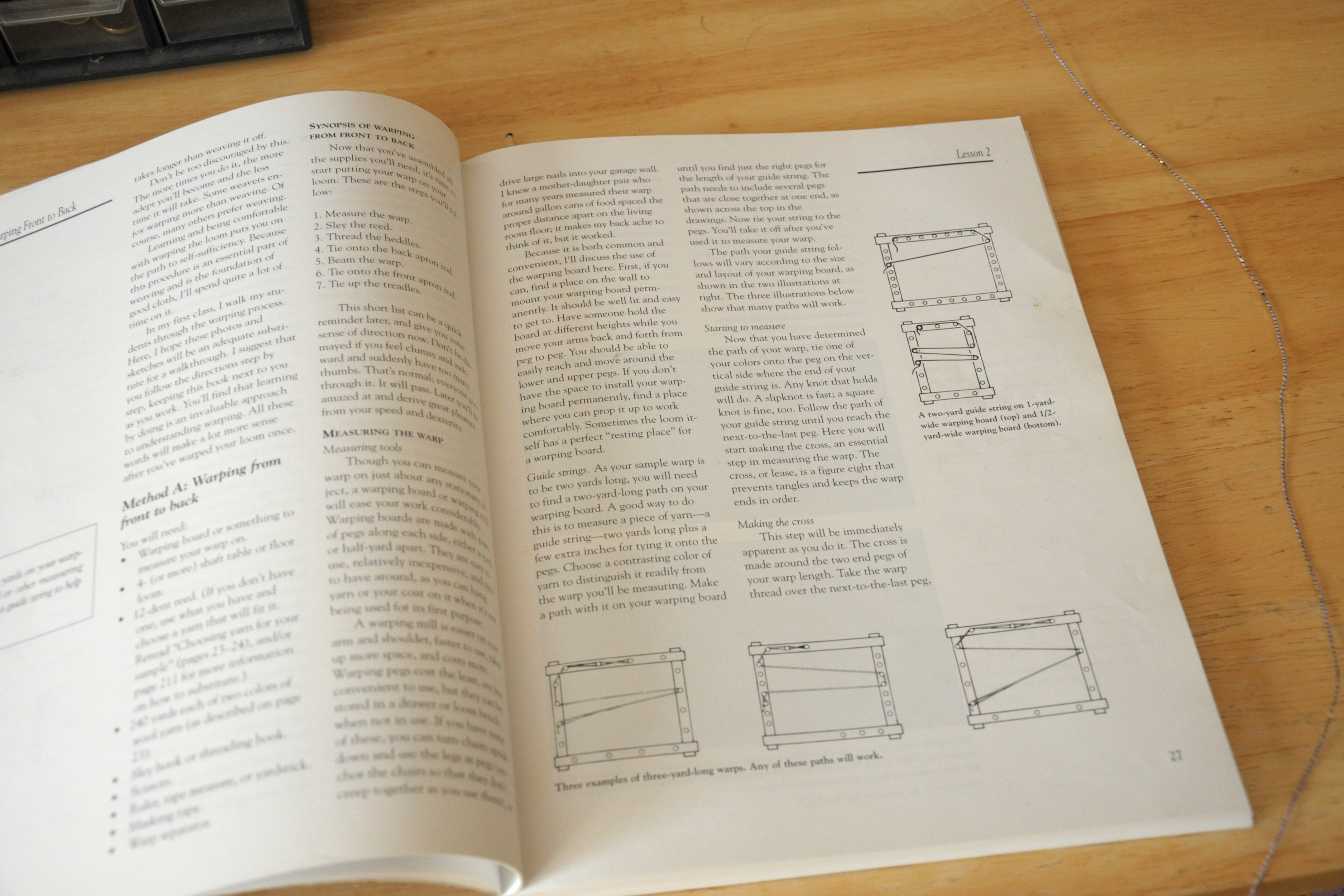

I bought this book when I first acquired ol’ Fanny, and it has proven to be an indispensable resource. Deborah has so many little tips “woven” throughout this book, along with super helpful illustrations. Though the book covers warping a floor loom front-to-back or back-to-front, I’ve only ever done the back-to-front method.

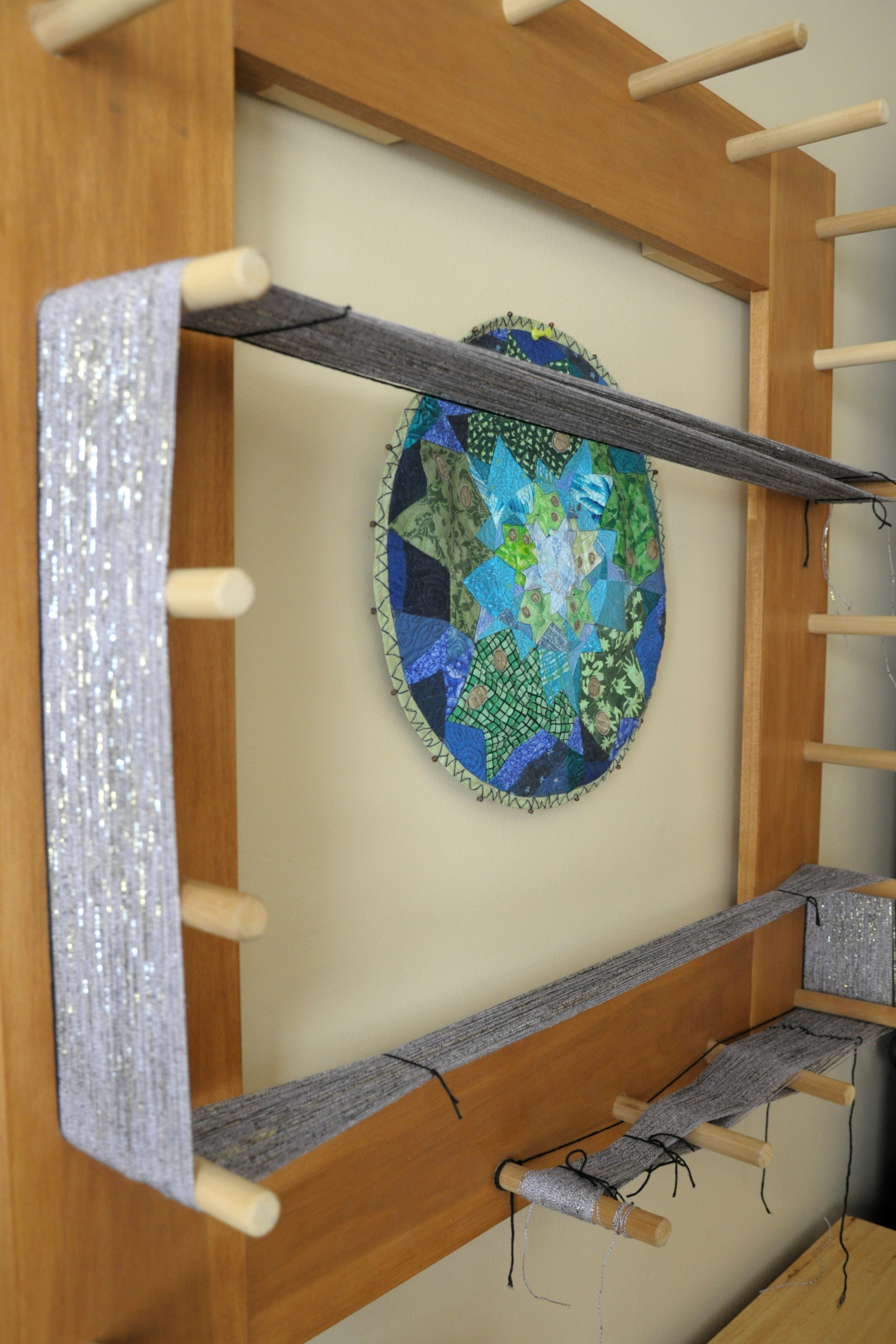

Rigid heddle looms are wonderful and can typically be direct-warped. This is not the case with a floor loom. So off to my warping board I went to begin the process.

This part of my warp shows the ultra-important figure 8 cross at the end. This will help me keep all my strands aligned when I take the bundle over to the loom.

I like to look head-on at the cross periodically as I’m winding my yarn to make sure things are going accordingly. As you can see below, I made a mistake that had to be taken out:

Get a load of that shimmer!

It’s crucial to tie the cross end in 5 places to keep it intact during the warping process.

That board with the nails in it that’s clamped to the back beam – that’s called a “raddle.” It’s just another tool that helps to separate the warp every inch-worth of warp threads.

After attaching the warp to the back rod, it’s time to thread the heddles. With rigid heddle weaving, the heddles are all part of a rigid piece of plastic (usually). With my floor loom, all the heddles are individual little pieces of metal.

So shimmery!

The main lace pattern that I’m going to be weaving is a repeat of 6 (more on this later). So I have to thread the shafts in this order: 1, 3, 1, 3, 1, 2. After each group of 6, I tie the 6 ends together in a little bundle to help keep them separate, and also so they don’t accidentally slip out of the back side of the heddles.

Once my warp was attached to Fanny, it was time to get ready to weave! I love to use boat shuttles with my floor loom, especially when my weaving width is wider than 12″ or so. With a flick of the wrist, the shuttle glides effortlessly over the warp threads. Though I don’t mind a stick shuttle and can eventually get a nice rhythm going, a boat shuttle just feels easier.

My boat shuttle takes small bobbins that the weft yarn must be wound onto. I could do it by hand, but it goes super-fast if I use the bobbin winder on my sewing machine. So that’s what I do!

Join me next time when I get down to business and start weaving!

(Update: there is a written version of this pattern on our website here.)

One Reply to “Weaving Wednesday – Getting my Sparkle On”

Comments are closed.