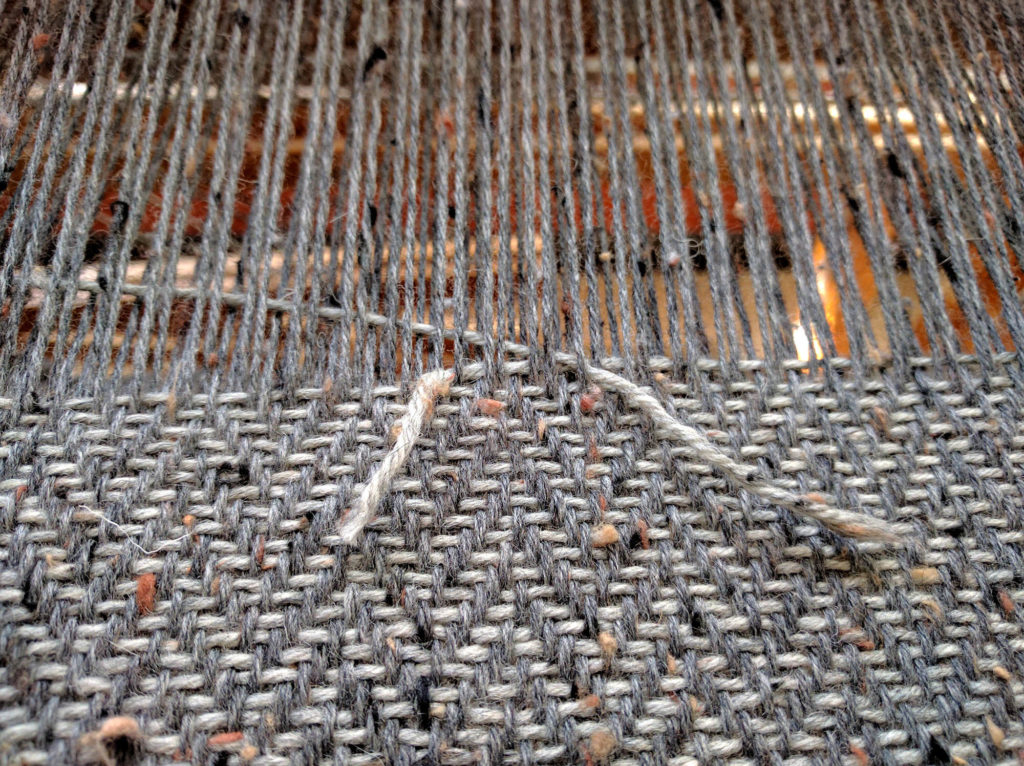

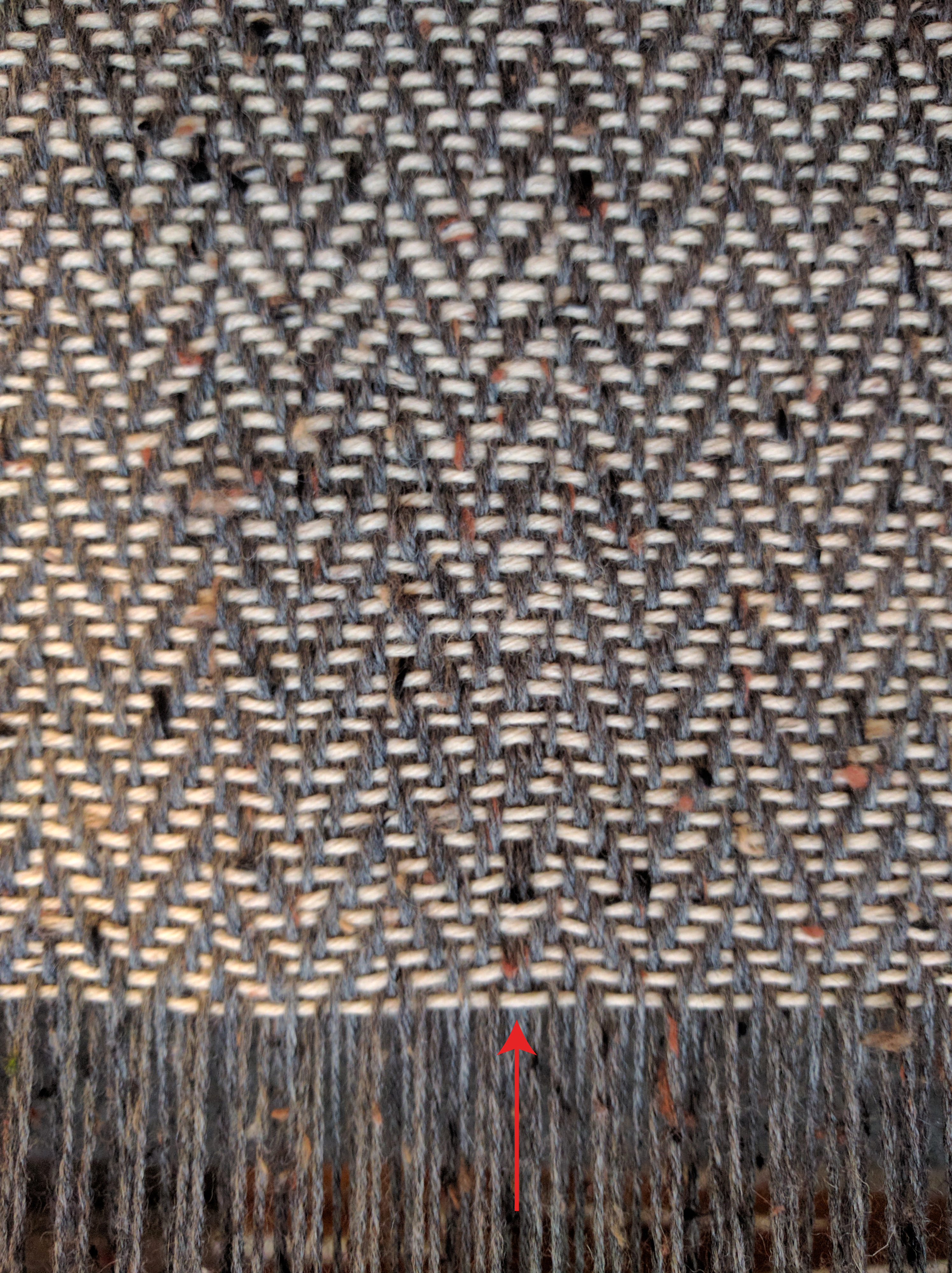

Finally, after sampling for my fabric (and getting a cool scarf in the process),

warping 280 inches of 432 ends,

it was time to sew jackets!

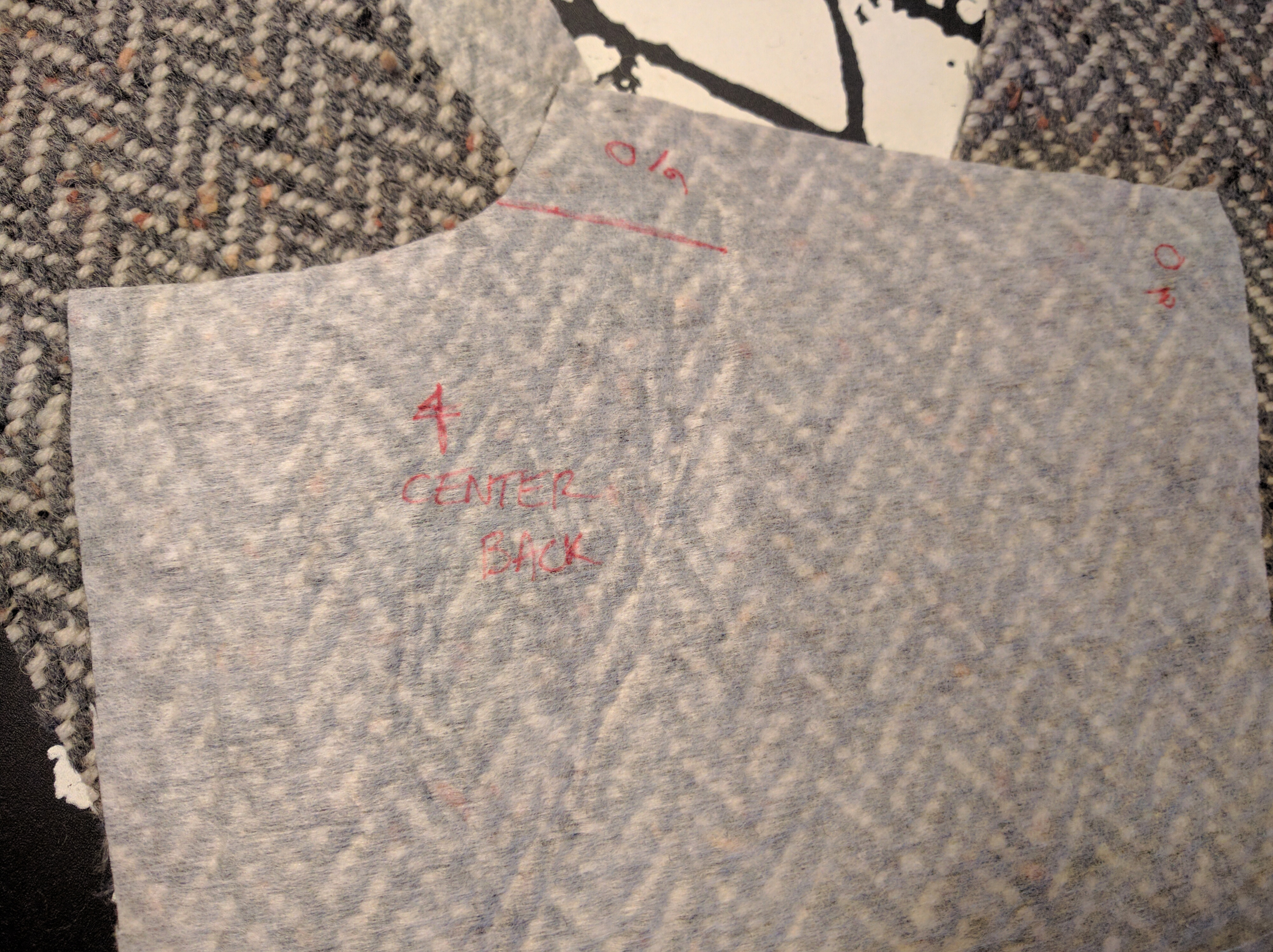

The first step was to interface all of my handwoven fabric. I got enough lightweight fusible interfacing for all my yardage. The reason for doing this is so that when I cut into the fabric for my pattern pieces, it will prevent the edges from coming unwoven.

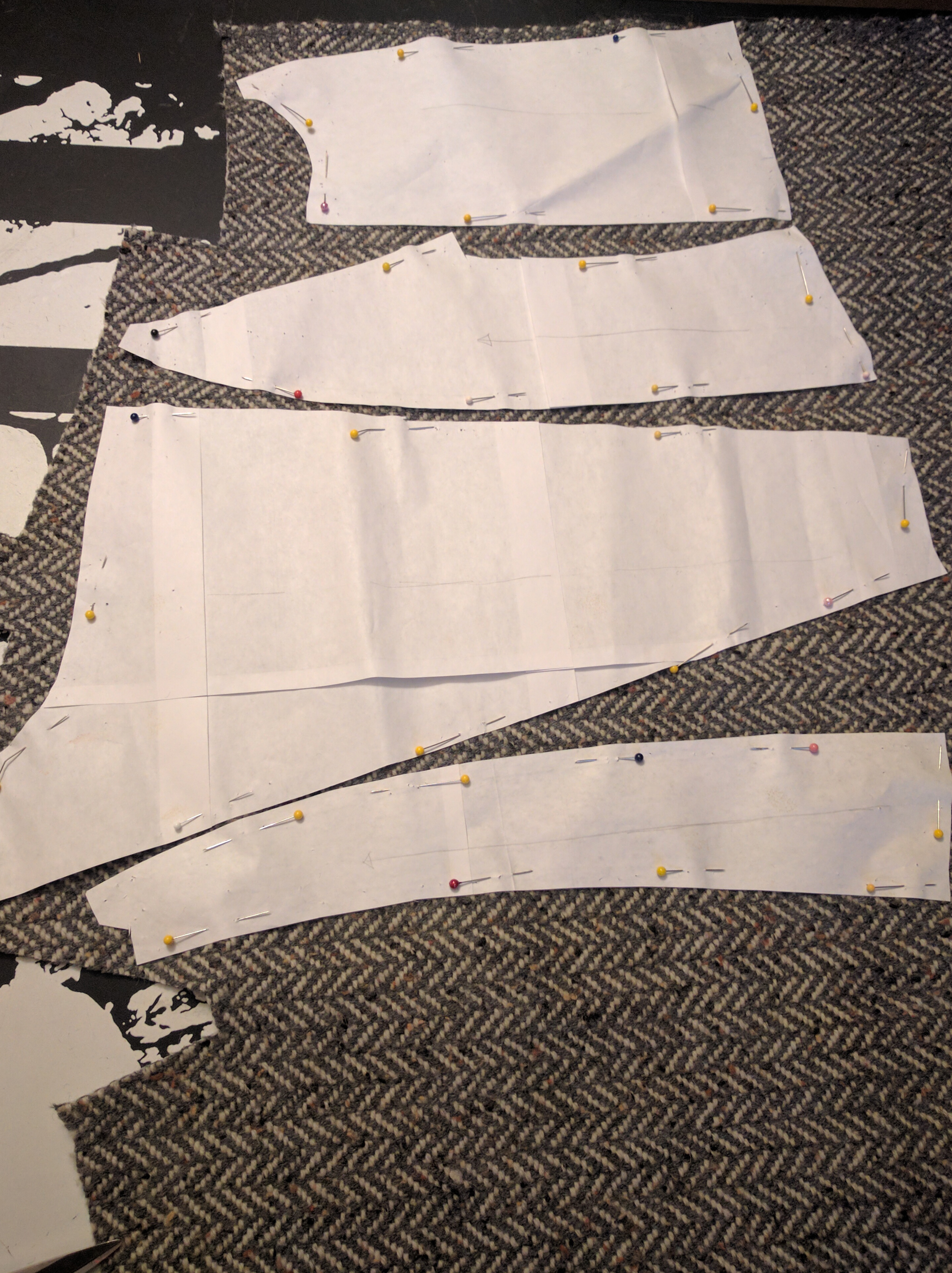

Two jackets-worth of pattern pieces and lining is a LOT of cutting!

Every bit of fabric is precious since I wove it, so a certain strategy is involved when laying out those pattern pieces.

With the interfacing on the back of my fabric, it made it easy to make pattern markings and actually be able to see them.

I used a special foot on my sewing machine called a “walking foot” for some of the bulky seams. It helps to manage bulky layers of fabric so that they feed evenly through the machine.

Sewing moto jackets requires a lot of coffee.

Since this is a weaving column, I’m taking it easy on sharing every single detail of the sewing process. But zipper installation fascinates me, so here are some in-progess shots of the pocket zippers. Above, I’m sewing the lining onto the right side of the fabric.

Then the pocket opening is slashed down the center.

Next, the lining fabric gets pulled to the wrong side and pressed. It’s so clean and tidy looking!

And finally the zipper is pinned underneath and sewn down. I love a good zipper installation. Which is good, since each jacket requires 5 zippers. Whew!

Here we have something that is actually beginning to resemble clothing. Yay!

If you’re planning on being at TNNA in San Jose this weekend, stop by the booth and check out the finished jackets. Otherwise, I’ll be back on the blog next week for final photos and wrap-up.